Custom Intermediate Bulk Containers

Quality, Custom-built Stainless Steel, Intermediate Bulk Containers (IBC) and Replacement Parts.Quality manufactured Intermediate Bulk Containers; IBC Totes in sizes from 120 to 793 gallons for transporting hazardous materials to 49 CFR requirements. There are standard sizes or a bulk container can be fabricated to your unique dimensions. Material construction is carbon steel and 304/316 stainless steel containers or to your specifications.

All IBC’s Intermediate Bulk Containers are fabricated, constructed and UN approved to 49 CFR 31A. Each tank is tested and labeled with the corresponding stainless steel information and unique serial number and registered in AMI’s computer data base for tanks. With this UN certification the tanks are DOT approved for transporting and handling hazardous materials.

Standard IBC transportable tanks are produced with common components. Material is heavy duty 10 gauge 304 stainless steel construction with a 2B finish. General tanks have a base dimension of 42” x 48”, but standard tanks can also be produced with 42” x 42” or 48” x 48” base dimensions.

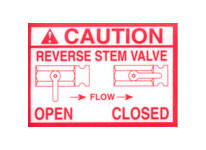

Standard Intermediate Bulk container tanks include; one piece slope bottom head towards the outlet valve, with a one piece standard ball valve and shipping plug. To protect the outlet valve there is a formed valve guard the length of the tank. The top head is constructed with a 22-1/2” manway opening and a portable tank (PT) cover, clamp ring, EPDM multi-seal gasket and a safety vent plug. The top head also includes four heavy duty ¼” thick lift lugs and leg positioners. Additional standard features include common safety labels, formed oval legs and a stainless steel ID/retest tag.

Request A Quote

"*" indicates required fields

Customization

Another area of AMI’s expertise is Intermediate Bulk Containers with special requirements and custom fabrication. Both the top and bottom heads can be modified with approved custom components for your product and process. The tank interior can be processed with ground seams, and the IBC can be passivated or electropolished.

Custom components for the IBC Tote® top head can include cam and groove fittings, male and female threaded pipe fittings and either light or heavy duty sanitary fittings. Special openings including manways and sight tubes are also available. Any requirement that your process needs can be accomplished.

The tank bottom head can be fabricated without a valve or with the valve of your choice. The standard valve can be changed to include a smaller or larger size depending on the application. Other options include sanitary valves or butterfly valves in various sizes and connections. AMI’s most popular valve is a sanitary connected 2” 3 piece valve with a 15 degree quick connect male adapter outlet.

The tank interior weld seams can be ground for a tank interior that is easier to clean and maintain. AMI’s production team will grind the weld seams flush to the tank wall and polish to your specifications. Additional special features are passivating the tank inside and outside, and electropolishing to a clean bright finish to the specification of you choice.

AMI’s standard and custom IBC tanks are widely used for many applications and industries. The paint and coatings industry use AMI IBC’s for bottom coat, top coat and ISO applications in the automotive industry. Other paint applications include paint and varnish; special processing, adhesives, metal fabrication, water process and electric lighting companies. Many also use AMI’s mixer agitators and drive motors to maintain the products blending in the tank before and after use. Other industries that use AMI tanks include; pharmaceuticals, oil and gas, food processing and many other applications where IBC Tote® tanks can be used to lower cost and improve efficiently.